Features and functions of a computerized metering device for zigzag patterns

2024-04-12

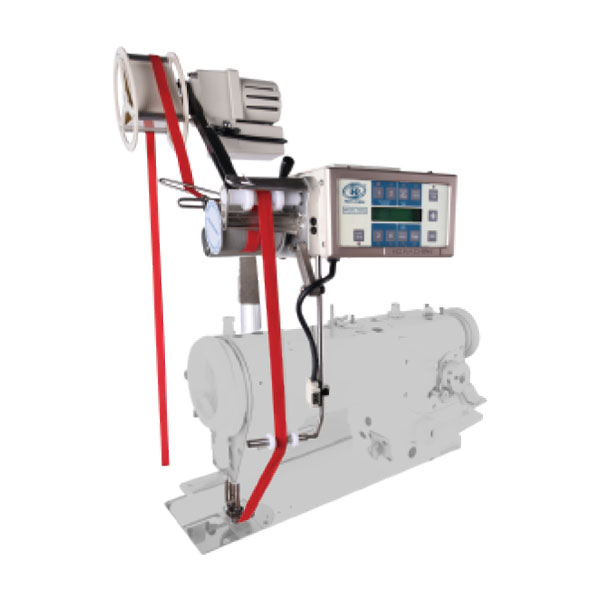

A computerized metering device for zigzag patterns is a specialized piece of equipment used in textile manufacturing to accurately control the metering and feeding of yarn or thread in zigzag stitch patterns. These devices are commonly used in sewing machines, embroidery machines, and other textile production equipment to create decorative or functional zigzag stitches with precise spacing and tension. Here's an overview of the features and functions of a computerized metering device for zigzag patterns:

1. Digital Control Interface: The device is equipped with a digital control interface that allows operators to input parameters such as stitch length, stitch width, stitch density, and pattern type. The interface may include a touchscreen display or buttons for easy navigation and adjustment of settings.

2. Programmable Stitch Patterns: The computerized metering device can store and recall multiple pre-programmed zigzag stitch patterns, including variations in stitch length, width, density, and direction. Operators can select the desired pattern from a menu or create custom patterns using the programming interface.

3. Precise Metering and Feeding: The device accurately meters and feeds yarn or thread through the sewing or embroidery machine at a consistent rate, ensuring uniform stitch formation and pattern alignment. Advanced servo or stepper motor technology is often employed to achieve precise control over the feeding mechanism.

4. Variable Speed Control: Operators can adjust the speed of the metering device to match the requirements of the stitching process, allowing for optimal performance and stitch quality. Variable speed control helps prevent thread breakage, puckering, or other issues that may arise from excessive or insufficient feeding speed.

5. Tension Adjustment: The computerized metering device may include built-in tension adjustment mechanisms to control the tension of the yarn or thread as it is fed through the machine. Proper tension adjustment is essential for achieving balanced and uniform zigzag stitches, especially when working with different types of fabrics or threads.

6. Automatic Thread Trimming: Some advanced models of computerized metering devices feature automatic thread trimming functionality, which automatically cuts the thread at the end of each stitch or pattern sequence. This helps streamline production processes and reduce manual labor requirements.

7. Integration with Sewing or Embroidery Machines: The computerized metering device is designed to integrate seamlessly with sewing machines, embroidery machines, or other textile production equipment. It can be mounted directly onto the machine or connected via interface cables for synchronized operation.

8. Diagnostic and Maintenance Features: The device may include diagnostic tools and maintenance reminders to monitor its performance and alert operators to any issues or maintenance requirements. This helps minimize downtime and ensure reliable operation over time.

Overall, a computerized metering device for zigzag patterns offers precise control, versatility, and efficiency in textile manufacturing applications, enabling the production of high-quality zigzag stitches with consistent results. Its advanced features and programmable capabilities make it an essential tool for modern textile production facilities.