Information about car bumper mold base

2024-03-21

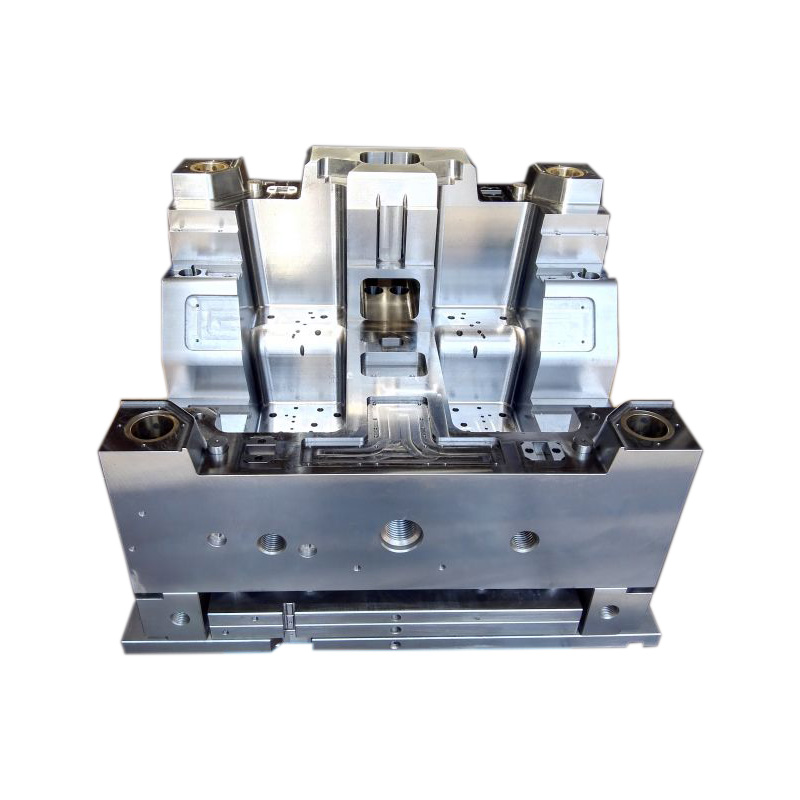

A car bumper mold base typically refers to the foundational component of a mold used in the manufacturing process of car bumpers. Let's break down what this entails:

1. Mold Base: The mold base is the main structural component of a mold assembly. It provides the framework and support for all other components of the mold, including cavities, cores, inserts, and cooling channels. The mold base is typically made from high-quality steel or aluminum alloy to withstand the pressures and temperatures of the injection molding process.

2. Design Considerations: The design of a mold base for car bumpers must take into account the specific shape, size, and features of the bumper being produced. This includes considerations for the overall dimensions of the bumper, any surface textures or details, and any special requirements such as mounting points or attachment features.

3. Cavities and Cores: Within the mold base, cavities and cores are machined to the precise shape and dimensions of the car bumper. Cavities create the outer surface of the bumper, while cores create any internal features or structures. These components are typically CNC machined to ensure accuracy and consistency.

4. Cooling Channels: To control the temperature during the molding process and facilitate efficient cooling of the molten plastic, cooling channels are incorporated into the mold base. These channels allow for the circulation of coolant, such as water or oil, to extract heat from the mold quickly and evenly, reducing cycle times and improving part quality.

5. Ejector System: An ejector system is integrated into the mold base to release the molded bumper from the mold once it has cooled and solidified. This system typically includes ejector pins or sleeves that push the part out of the mold cavity after the molding cycle is complete.

Overall, the design and construction of a car bumper mold base are critical aspects of the injection molding process, ensuring the production of high-quality bumpers that meet the required specifications and standards. Advanced machining techniques and materials are often employed to achieve the precision and durability necessary for efficient and reliable manufacturing operations.