Key aspects related to CNC machined aluminum parts

2023-10-17

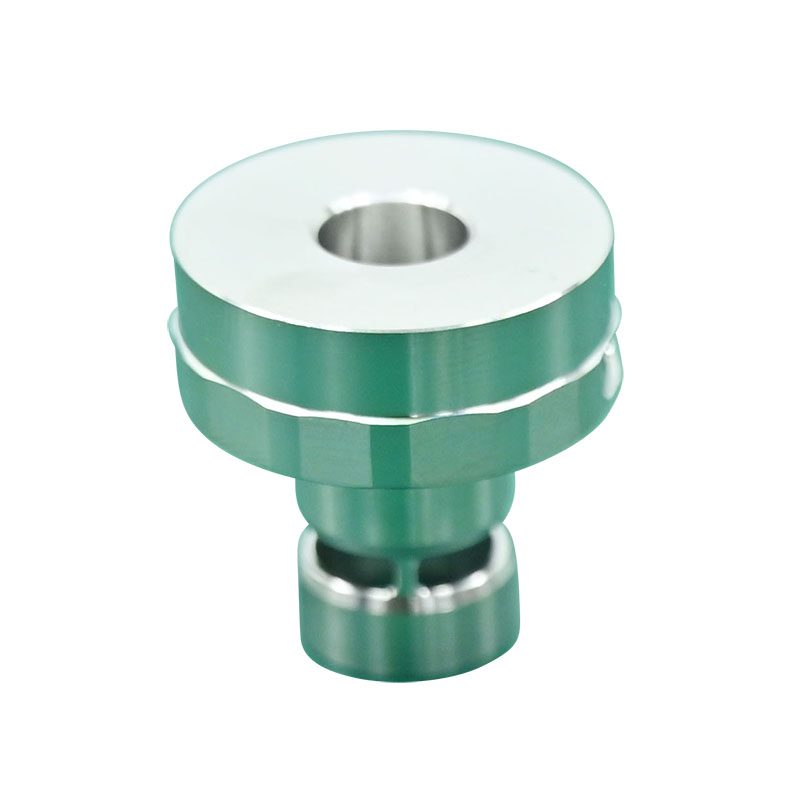

CNC (Computer Numerical Control) machining is a versatile and precise manufacturing process used to produce a wide range of parts and components from various materials, including aluminum. CNC machined aluminum parts are known for their high precision, durability, and versatility, and they find applications in many industries, including aerospace, automotive, electronics, medical devices, and more.

Here are some key aspects related to CNC machined aluminum parts:

1. Design and CAD Modeling: The process typically begins with the creation of a 3D computer-aided design (CAD) model of the part to be machined. The CAD model contains detailed information about the part's geometry and dimensions.

2. CNC Machining Process: CNC machining involves using computer-controlled machines, such as mills and lathes, to remove material from a block or sheet of aluminum to create the desired shape. The cutting tools are precisely controlled by the CNC program, ensuring accuracy and repeatability.

3. Aluminum Alloys: Aluminum comes in various alloys, each with its own properties, such as strength, corrosion resistance, and machinability. The choice of alloy depends on the specific requirements of the part.

4. Precision and Tolerances: CNC machining is known for its ability to achieve tight tolerances and high precision. This makes it suitable for producing complex and intricate aluminum components with exceptional accuracy.

5. Surface Finish: Depending on the machining process and tooling used, CNC machined aluminum parts can have different surface finishes, ranging from rough to polished. Surface finish requirements are often specified in the design.

6. Prototyping and Production: CNC machining is suitable for both prototyping and high-volume production. Prototyping allows engineers to test and refine designs before committing to large-scale production.

7. Complex Geometries: CNC machining can create parts with complex geometries, including features like pockets, holes, threads, and intricate contours.

8. Materials Compatibility: CNC machined aluminum parts are compatible with various surface treatments and coatings, including anodizing, plating, and powder coating, to enhance their appearance, corrosion resistance, and other properties.

9. Cost Factors: The cost of CNC machined aluminum parts depends on factors like material choice, complexity, tolerances, and batch size. Larger quantities can often lead to cost savings due to economies of scale.

Common CNC machined aluminum parts include:

- Aerospace components like aircraft structural parts and engine components.

- Automotive parts, including engine components, brackets, and suspension components.

- Electronics housings and heat sinks.

- Medical device components.

- Precision tools and fixtures.

- Consumer electronics parts.

Overall, CNC machined aluminum parts offer a combination of strength, light weight, and precision, making them a popular choice in many industries where high-quality components are required.