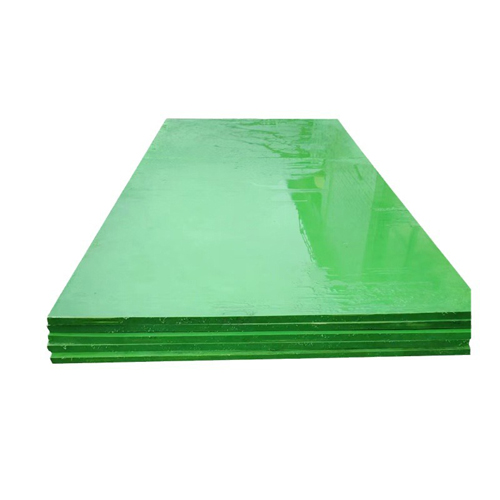

PE Board: A Durable and Versatile Plastic Solution for Industrial and Everyday Use

2025-05-08

PE Board, also known as Polyethylene Board, is a high-performance plastic sheet made from polyethylene, one of the most commonly used thermoplastics in the world. Known for its excellent chemical resistance, toughness, and flexibility, PE board is widely used across industries ranging from construction and packaging to marine and food processing.

What is PE Board?

PE board is manufactured using high-density polyethylene (HDPE), low-density polyethylene (LDPE), or ultra-high molecular weight polyethylene (UHMWPE), depending on the intended application. It is available in various thicknesses, colors, and surface finishes to suit specific needs.

Key Properties

High Impact Resistance: PE boards can absorb shocks and resist cracking or breaking.

Chemical and Corrosion Resistance: Excellent resistance to acids, alkalis, and organic solvents.

Waterproof and Moisture-Resistant: Ideal for humid and wet environments.

UV and Weather Resistance: Suitable for outdoor use, especially with UV-stabilized grades.

Low Friction Surface: Especially true for UHMWPE boards, making them suitable for sliding and wear applications.

Non-Toxic and Food-Safe: Certain grades are FDA-approved for use in food contact applications.

Common Applications

1. Cutting Boards

PE boards are widely used in kitchens and food processing plants due to their hygienic and non-absorbent surface.

2. Chemical Storage and Processing Equipment

Resistant to corrosion, PE boards are used to fabricate tanks, linings, and equipment parts.

3. Marine and Outdoor Structures

UV-resistant PE boards are perfect for boat parts, dock fenders, and outdoor signage.

4. Industrial Machinery Components

Used as wear strips, guide rails, and machine guards, especially in conveying systems.

5. Construction and Civil Engineering

PE boards serve as protective barriers, liners, or lightweight formwork panels.

6. Packaging and Transportation

PE boards are used to make reusable boxes, dividers, and pallets due to their strength and reusability.

Types of PE Board

HDPE Board: Strong, rigid, and widely used in structural and industrial applications.

LDPE Board: Softer and more flexible, suitable for lightweight and less demanding uses.

UHMWPE Board: Extremely tough and wear-resistant, ideal for high-impact or low-friction needs.

Advantages

Long service life

Lightweight and easy to handle

Easy to machine, weld, or thermoform

Recyclable and environmentally friendly options available

Conclusion

PE board is a practical and reliable material that offers outstanding durability, chemical resistance, and versatility. Whether you're manufacturing food-grade cutting surfaces, constructing marine equipment, or designing industrial machine parts, PE board provides an efficient and cost-effective solution. Its adaptability and eco-friendly potential make it a preferred choice across countless industries.