Purpose and Functions of Coil Cut To Length Machine

2024-07-09

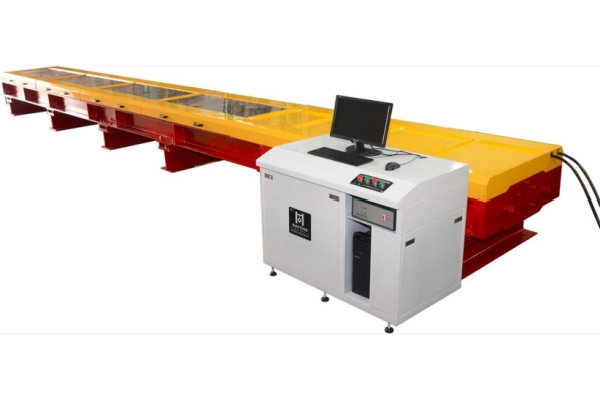

A metal material testing machine, also known as a materials testing machine or a universal testing machine (UTM), is a specialized equipment used to determine the mechanical properties of metals and other materials under various conditions. Here’s an overview of what a metal material testing machine entails:

Purpose and Functions

1. Mechanical Properties Testing:

- Tensile Strength: Measures the maximum tensile stress a material can withstand before failure.

- Compression Strength: Determines the ability of a material to withstand compressive forces.

- Flexural Strength: Assesses the resistance of a material to bending forces.

- Shear Strength: Measures the material's ability to withstand shear stress before failure.

2. Testing Methods:

- Tensile Testing: Pulls a sample to measure elongation, yield strength, ultimate tensile strength, and fracture point.

- Compression Testing: Applies compressive force to determine compressive strength and deformation behavior.

- Bending Testing: Applies a load to measure flexural strength and stiffness.

- Shear Testing: Applies forces parallel to the surface of the material to assess shear strength.

3. Components and Operation:

- Load Frame: Provides the structure and rigidity to apply forces to the test specimen.

- Force Measurement: Uses load cells or hydraulic systems to measure the force applied during testing.

- Deformation Measurement: Employs extensometers or strain gauges to monitor specimen deformation.

- Control Systems: Utilizes software and electronic controls to regulate the testing process and collect data.

Types of Tests

1. Static Testing:

- Steady Loading: Applies a constant load to measure the material's response over time until failure or deformation.

- Stress-Strain Analysis: Generates stress-strain curves to analyze material behavior under load.

2. Dynamic Testing:

- Fatigue Testing: Applies cyclic loading to assess the material's endurance limit and fatigue life.

- Impact Testing: Determines the impact resistance and toughness of materials subjected to sudden forces.

Applications

1. Quality Control and Assurance:

- Manufacturing: Ensures consistency and reliability of materials used in manufacturing processes.

- Product Development: Evaluates new materials and designs to optimize performance and durability.

2. Research and Development:

- Material Characterization: Investigates the mechanical properties and behavior of materials for specific applications.

- Failure Analysis: Identifies weaknesses or defects in materials to improve product reliability and safety.

Considerations

1. Accuracy and Calibration:

- Precision: Ensures accurate measurement and control of testing parameters.

- Calibration: Regular calibration of equipment to maintain accuracy and reliability of test results.

2. Safety and Compliance:

- Safety Features: Incorporates safety measures to protect operators and equipment during testing.

- Regulatory Compliance: Meets international standards (e.g., ASTM, ISO) for material testing procedures and equipment specifications.

Conclusion

A metal material testing machine plays a critical role in assessing the mechanical properties and performance of metals and other materials used in various industries. Whether for quality assurance in manufacturing or research in material science, these machines provide essential data to ensure product integrity and reliability.