Understanding Round Condenser Tubes: Function, Benefits, and Applications

2025-02-11

Round condenser tubes are essential components in various cooling and heat exchange systems. Found in industries such as HVAC, power generation, and refrigeration, these tubes play a crucial role in transferring heat efficiently. Their durability, thermal conductivity, and resistance to corrosion make them a preferred choice for many applications.

What is a Round Condenser Tube?

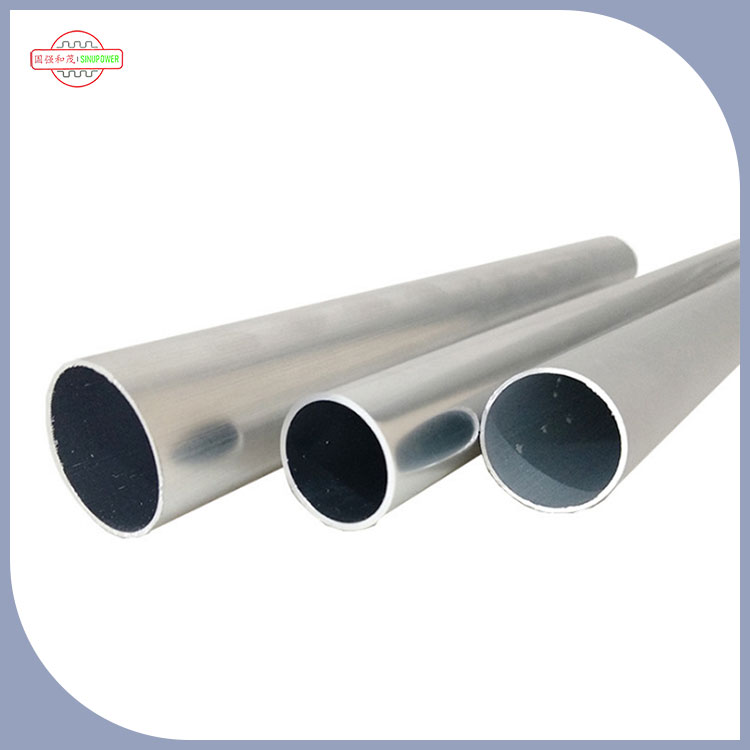

A round condenser tube is a cylindrical metal tube used in heat exchangers and condensers to facilitate heat transfer between fluids. Typically made from materials like copper, stainless steel, or aluminum, these tubes help dissipate heat efficiently by allowing a cooling medium, such as air or water, to flow around them.

The design and material of the tube are critical in ensuring optimal performance, as they impact conductivity, pressure resistance, and overall longevity.

Key Benefits of Round Condenser Tubes

1. High Thermal Conductivity

Round condenser tubes are designed for efficient heat exchange. Materials like copper and aluminum provide excellent thermal conductivity, allowing rapid cooling and condensation.

2. Durability and Corrosion Resistance

Many condenser tubes are made from corrosion-resistant materials such as stainless steel or coated metals, making them ideal for use in harsh environments, including marine and industrial settings.

3. Efficient Heat Transfer

The round shape of these tubes allows for uniform heat distribution and maximized contact with cooling fluids, enhancing overall efficiency in heat exchange systems.

4. Versatility in Applications

Round condenser tubes are widely used in various industries, from air conditioning units to large-scale industrial cooling systems. Their adaptability makes them a crucial component in many heat exchange processes.

5. Cost-Effective Solution

Due to their long lifespan and efficiency, round condenser tubes offer a cost-effective solution for cooling systems, reducing maintenance and energy consumption over time.

Common Applications of Round Condenser Tubes

1. HVAC Systems

Heating, ventilation, and air conditioning systems rely on condenser tubes to regulate temperature by transferring heat efficiently. These tubes are essential in residential and commercial air conditioning units.

2. Refrigeration Systems

In commercial and industrial refrigeration, condenser tubes help cool down and condense refrigerants, ensuring optimal performance in food storage and transport systems.

3. Power Plants

Thermal power plants use round condenser tubes in steam turbines to cool down steam after it has passed through the turbines, helping to recycle water efficiently.

4. Marine and Industrial Cooling Systems

Ships, offshore platforms, and industrial facilities use these tubes for cooling purposes, as they are resistant to corrosion and harsh environmental conditions.

5. Automotive and Aerospace Applications

Round condenser tubes are used in vehicle cooling systems, helping regulate engine temperatures and prevent overheating. Aerospace applications also benefit from their lightweight and high-strength properties.

Choosing the Right Round Condenser Tube

When selecting a round condenser tube, factors such as material, wall thickness, diameter, and environmental conditions should be considered. Copper tubes are preferred for their superior heat transfer properties, while stainless steel tubes are chosen for their corrosion resistance and durability.

Conclusion

Round condenser tubes are an integral part of heat exchange and cooling systems across multiple industries. Their efficiency, durability, and adaptability make them a valuable component in HVAC, refrigeration, power generation, and more. Choosing the right material and design ensures optimal performance, energy efficiency, and long-term reliability in various applications.